The company GALVAN CZ s.r.o. performs surface treatment by wet low-pressure manual painting of metal materials.

The surface for painting is prepared by blasting or phosphating. Polymerization chamber furnaces are part of the painting technology.

Painting takes place in painting boxes measuring 6 x 4 x 3.5 m. The company GALVAN CZ s.r.o. specializes in the following types of protective coatings:

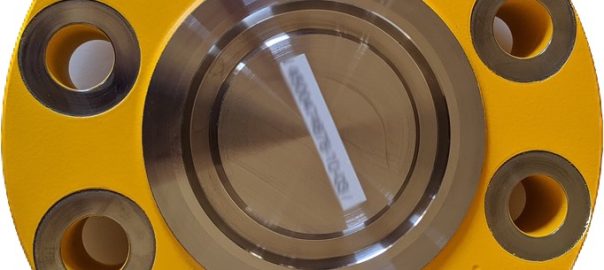

Xylan® from PPG Whitford – painting with technical plastics XYLAN PTFE.

MOS2 – sliding coatings based on molybdenum sulfate. We use Ever-Slik® by Everlube® Products Curtiss Wright.

Intertherm 3070 Epoxy Protective Coatings – Two component phenolic epoxy, designed specifically for the subsea market. Novolac with excellent resistance to high temperatures and compatibility with cathodic protection.

We also use PPG’s PHENGUARD™ 780, which is a two-component, high strength, amine adduct cured novolac phenolic epoxy primer.

The painting process is inspected by FROSIO LVL III, so our services are of the highest quality.

Technical coatings are widely used in the automotive, chemical, food, mining, plastic or paper industries.

The main advantages of technical coatings:

corrosion resistance,

abrasion resistance,

Improvement of mechanical properties,

Resistance to high temperatures,

Chemical resistance,

Extending the life of parts.

Examples of specifications used:

NORSOK M-501

X-004022 (Everslik 1201/1301)

C81000 (Red XYLAN)

C81001 (XYLAN Green)

C81005 (yellow XYLAN)

C81006 (Orange XYLAN)

C81007/C81015 (Black XYLAN)

C80400 (Phosphating)

Everslik (Black / Grey)

Epoxy paints (color according to customer requirements).